Order Picking in Bitlog WMS: Relay Picking

At the Bitlog Summit, we unveiled a new, groundbreaking picking method in Bitlog WMS: Relay Picking. Developed in collaboration with our customer Nordic Nest, Relay Picking is not for everyone. However, if you have conveyors and wish to merge automation with manual picking, this is undoubtedly the ultimate picking approach for you.

What is Relay Picking?

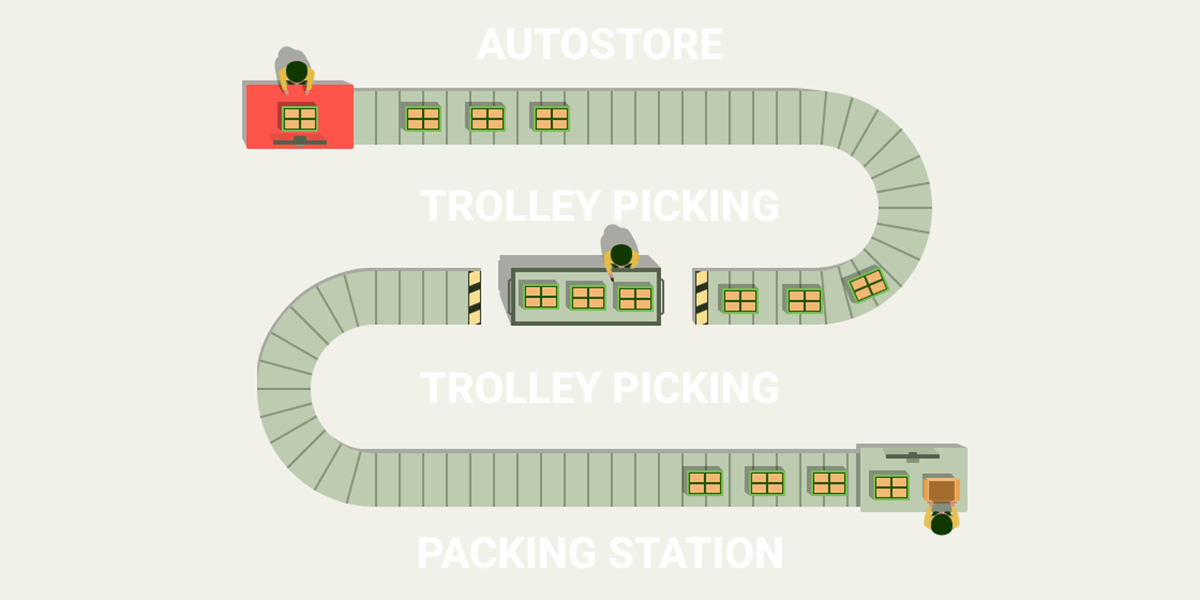

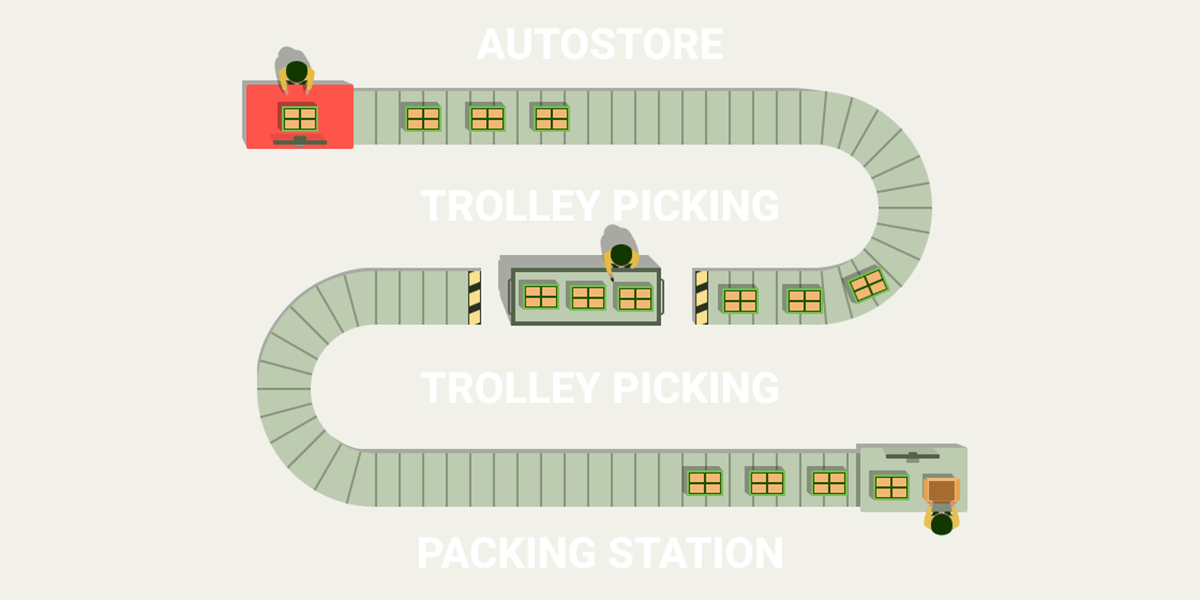

Relay picking is exactly what it sounds like. It is a picking method where an order is picked in multiple stages, or relays. It can start in your AutoStore and then pass through various picking zones in your warehouse before the order is consolidated and sent to the packing station via conveyor belts.

Image: Simplified visualization of how relay picking could work in a warehouse.

Advantages of Relay Picking

There are numerous advantages to implementing relay picking if you have advanced automation, conveyor belts, or complex order picking. Here are some benefits of using relay picking as a picking method in your warehouse:

-

Bitlog recommends the most optimal Relay Picking route based on volumes, zones, and products. You can save valuable time by avoiding the need to plan complex order picking.

-

Even though an order may pass through multiple zones/areas and be fulfilled using different picking methods, the entire order is picked and consolidated in a single box.

-

Reduces the need for consolidation (family picking) to save time.

-

The box you pick your order in will automatically be directed to the next "relay stage" of the conveyor belt.

Key Features

-

Pick the order in a single container, even if the items are in different zones/areas.

-

Handles consolidation (if necessary)

-

Connected to Bitlog WMS Autopilot

Nordic Nest 💚 Bitlog WMS

Nordic Nest is embarking on an incredibly exciting journey of automation. The e-commerce giant built a new warehouse in 2021, only to discover it was too small from day one. They experienced rapid growth while waiting for the new facility. After two quick expansions, they decided to invest in an AutoStore, seamlessly integrated with Bitlog WMS.

The next step is to invest in additional automation, such as conveyor belts and automated packing stations. This project is already well on its way to completion!

At Bitlog, we are humbled and thrilled to be a part of this journey. It is our users who ensure that our products evolve in the right direction and improve with each new upgrade we release.

See the full Nordic Nest customer story here >

Story by

The Bitlog Team